Restauro motore elaborato Lambretta 250cc - Alberto Ancillotti, Firenze, Italia

Sometimes you get to do things that make a significant change to your day, month and life…. That happened to the RLC Crew when we had the privilege of wining and dining with none other than Alberto Ancillotti. Thanks to one of RLC’s exhaust makers, Claudio Calonicci, we got to pass the evening with the living legend and hear some tales first hand. The evening passed by in a flash but we got to hear of the Ancillotti Bros’ trip to Elvington in the 60’s (as part of a fully-paid for publicity stunt by UK parts & accessories wholesalers Nannucci), what they tried that worked , and didn’t work, where they got their parts made and ideas from, the rise and fall of their Tuscan factory……the list is endless. And priceless. Alberto Ancillotti is a humble, quiet person who seemed in awe of the fame that scooterists hold for his family surname, Worldwide.

The original 250cc Ancillotti sprinter was severely damaged when Florence was flooded in the mid 60s’ and in his own words, “it ended up in 3 metres of dirty river water”. A few years ago, the engine from the scooter was given to a scooter shop to sort out but never completed. After initially being approached by Alberto, we arranged to have the parts collected on his behalf so we could complete the job of getting his sprinter sorted out and brought back to life.

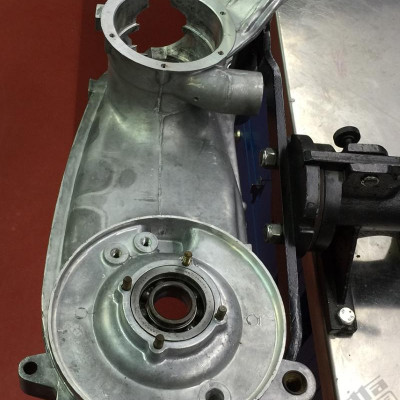

Due to ending up later-logged with corrosive river water, EVERY single component of the engine was covered in caked on muck and grime like nothing we’d ever seen. Not so much for the quantity but for the fact that it just wouldn’t budge. It took HOURS AND HOURS to clean up and the bright side of this was that we found a ‘new’ (to us) product that did the job handsomely. The finish of the engine had to be ‘period-correct’ and not acid dipped which is too ‘custom’ for something of this historical importance. Once cleaned up, we had the gasket faces lightly skimmed to ensure perfectly sealing surfaces.

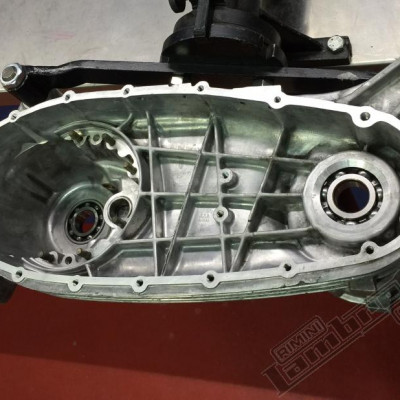

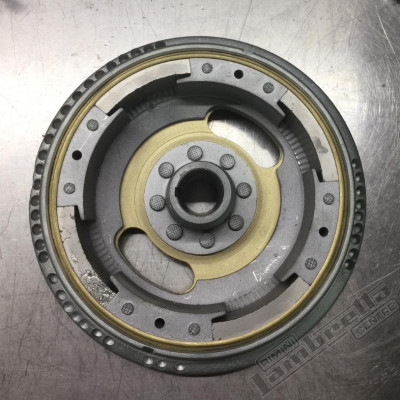

The inner components were checked and checked. The parts we were given were the complete top end complete with unique 72mm diameter Asso piston (that they made especially for the Ancillotti bros.), a heavily modified TV175 Series 1 crankshaft, a special one-off 20 tooth front sprocket arrangement that had been modified to drive a Smiths rev-counter (the outer engine sidecasing has a brass oval attached where they had started the job but never completed it), a lightened and much simplified 4 pole Ducati ignition, a modified flywheel flange (to take 2 special bearings and a single external oilseal) and a very battered exhaust complete with a 4 stud fixing U bend. Unfortunately, over the years, the complete gearbox had been ‘lost’ as had the Dell’Orto carb and manifold.

For the anoraks, the engine casing itself is a unstamped Innocenti TV200 / early SX200 casing that is completely standard (transfers included) other than having a hand-ground recess added into the crank area to allow the 60mm stroke crankshaft to spin freely.

The rebuild was carried out personally by Dean, with some assistance from Lorenz, and once everything had been checked and sourced, the job was (reasonably) easy. The complete gearbox needed to be sourced so once we sat down and did some maths we worked out what had been used back in the day. The clutch was only ever going to be a beefed-up 4 plate unit with mental springs so to keep it period correct, that was what we fitted. The only major issues were the crankshaft that had arrived already rebuilt (by the aforementioned scooter shop) but was found to be drastically off-centre so that needed sorting. Then we noticed that the chain alignment was seriously way off. We’d had our suspicions when checking the off-set grooves carved into the rubber strip of the Ancillotti top chain guide and the fact that the front sprocket is an industrial machinery part, that had been modified and then subsequently welded to a TV1 ‘base’. Another major headache was the top end which although had arrived stripped down, it was obvious that it had spent a LOT of years completely seized solid and the wafer thin barrel was SERIOUSLY pitted and actually cracked on the base spigot. This is the heart of the whole show so could not be changed, so after countless hours we managed to get it as-near-as-dammit to be serviceable and hopefully it’ll now be okay. The last part of the puzzle was the exhaust unit which had a whole section rotted away on the U bend (made of very heavy plumbers tubing). Once replaced it all aligned up and the engine is now as you see it here.

Tomorrow (11.10.2016) the engine is heading back to Florence into Alberto Ancillotti’s hands and it has been a real honour for us to have been entrusted with such a prestigious piece of scootering history. Alberto now has plans to refit the engine to the scooter and we’ll keep you posted on how he progresses. It might be constructed of ‘simple’, almost crude components compared to what we have available for our engines today, but it still hit 108mph back in the day and that is definitely NOT to be sniffed at. Respect.

- Modello:

- Ancillotti Lambretta 250cc da Record

- Proprietario:

- Flli. Ancillotti, Firenze, Italia